Power Factor Correction: Why It Matters

Why This Topic Should Matter to You

Have you ever opened your electricity bill and wondered why the numbers don’t match your actual energy usage? You switch off unnecessary lights, keep your machines well-maintained, and even monitor peak-hour consumption, but still, the bill feels inflated. The culprit often hides in plain sight — a poor power factor.

When your power factor is low, you’re not just using energy inefficiently, you’re paying for wasted electricity. That wasted power silently drains your wallet and places unnecessary stress on the power grid. The good news? You can take control of it through Power Factor Correction (PFC). This simple yet powerful solution helps you cut costs, boost efficiency, and even contribute to a more sustainable energy future.

Table of Contents

Understanding Power Factor – The Basic

What is Power Factor?

At its core, power factor measures how efficiently you use electrical energy. It’s the ratio of real power (the part that actually does useful work, measured in kilowatts) to apparent power (the total supplied, measured in kVA).

Think of it like filling a cup:

- If you pour water straight into the cup without spilling, you’re at unity power factor (1.0).

- If you spill half on the table, you’re wasting effort — that’s a poor power factor.

A higher power factor means you’re using electricity effectively. A low power factor means inefficiency and higher costs.

Formula and Practical Example

The formula is straightforward:

Power Factor = Real Power (kW) ÷ Apparent Power (kVA)

- If your factory uses 90 kW of real power but draws 100 kVA, your power factor is 0.9.

- If you draw the same 100 kVA but only use 50 kW effectively, your power factor drops to 0.5 — a red flag.

Table: Power Factor Comparison

| Power Factor | Efficiency Level | Impact on Bills | Example Scenario |

|---|---|---|---|

| 1.0 (Unity) | Excellent | Lowest costs | Modern efficient systems |

| 0.9 | Good | Slightly higher bills | Light inefficiencies |

| 0.7 | Poor | Noticeably higher bills | Motors running under load |

| 0.5 | Very Poor | Heavy penalties | Outdated equipment |

Why Power Factor Correction Matters

Financial Benefits You Can’t Ignore

- Lower Bills: By correcting your power factor, you reduce wasted energy and avoid penalties from utilities.

- No Hidden Charges: Many power providers penalize users with a poor power factor — correcting it helps you dodge these costs.

- Demand Charges: With a better power factor, you pull less reactive power from the grid, lowering your demand charges.

Technical Advantages That Improve Your System

- Free Up System Capacity: Correction reduces the unnecessary load on transformers and cables, allowing you to power more equipment without upgrades.

- Better Voltage Regulation: Corrected systems experience fewer voltage drops, leading to smoother operation of machines.

- Reduced Losses: Heat and line losses in cables decrease, extending equipment lifespan.

Environmental Impact

Improving your power factor isn’t just about saving money — it’s about saving energy. Reduced wastage means fewer fossil fuels burned, lower emissions, and a greener footprint. Every step you take toward energy efficiency supports sustainability.

Common Causes of Poor Power Factor

Here are the main reasons you might face a low power factor:

- Inductive Loads: Motors, transformers, and welding machines draw reactive power.

- Old Lighting: Fluorescent lamps and traditional ballasts can hurt your power factor.

- Non-Linear Electronics: Computers, UPS systems, and variable frequency drives (VFDs) distort power quality.

- Oversized Motors: Running motors under light load reduces efficiency drastically.

These culprits silently eat into your profits if you don’t address them.

How Power Factor Correction Works

Capacitor Banks

Capacitors supply reactive power locally, reducing the amount drawn from the grid. This balances out inductive loads and boosts your power factor closer to unity.

Automatic Power Factor Controllers (APFC)

APFC panels continuously monitor your power factor and switch capacitor banks on or off as needed. This ensures stability without manual intervention.

Synchronous Condensers & Advanced Solutions

For heavy industries, synchronous condensers or specialized filters offer powerful correction, especially in systems with harmonics.

Real-Life Applications of Power Factor Correction

Table: Power Factor Correction by Sector

| Sector | Typical Problem | Common Solution |

|---|---|---|

| Manufacturing | Heavy motor loads | Capacitor banks |

| Commercial | Lighting & HVAC loads | APFC panels |

| Data Centers | Non-linear electronics | Harmonic filters + APFC |

| Residential | Small inductive devices | Plug-in capacitors |

Whether you run a factory, office, or data center, implementing correction solutions pays off quickly. Even homeowners with multiple appliances benefit by reducing unnecessary strain.

Steps to Implement Power Factor Correction

Here’s a roadmap you can follow:

- Conduct a Power Audit: Use analyzers or consult your utility for power factor data.

- Identify the Culprits: Pinpoint machines or systems dragging your power factor down.

- Choose the Right Method: Capacitors, APFC, or condensers depending on scale.

- Install Correction Devices: Place them strategically near problem loads.

- Monitor and Maintain: Regularly check for fluctuations and update solutions as your system grows.

Cost-Benefit Analysis

Correcting your power factor does involve investment, but it pays back fast.

- Cost: Installation of capacitor banks or APFC panels.

- Savings: Reduced demand charges, lower energy wastage, avoidance of penalties.

- ROI: Most users see payback within 1–3 years.

Case Study Example:

A mid-sized factory consuming 200 kVA reduced its power factor from 0.65 to 0.95. The result? A 15% drop in monthly electricity costs and improved machine performance.

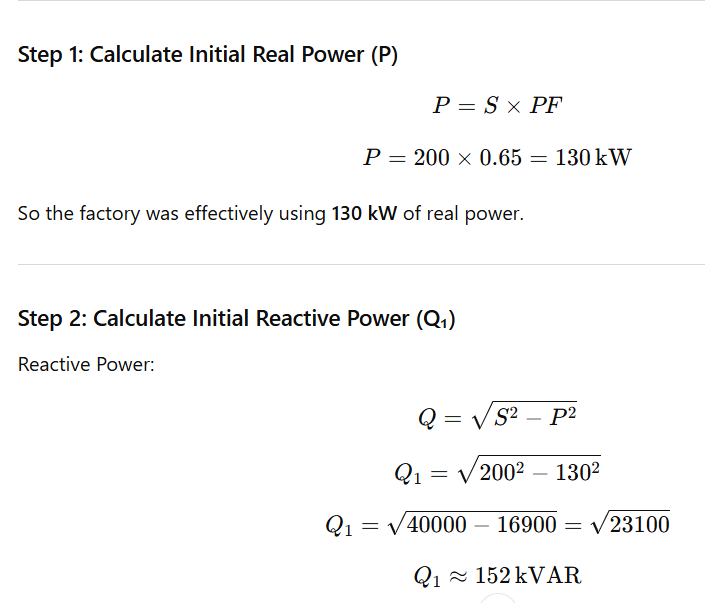

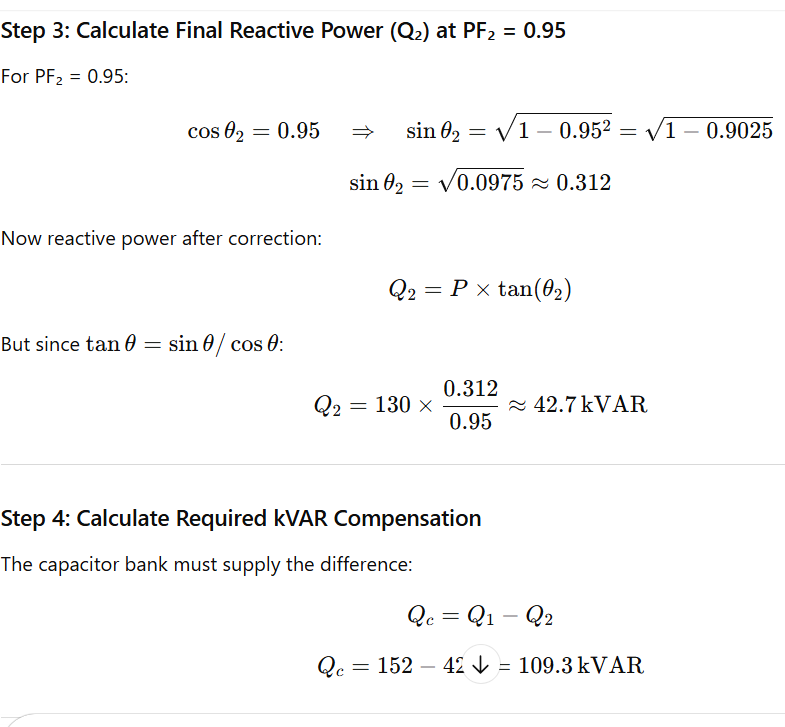

We’re told:

- Apparent power (S) = 200 kVA

- Initial Power Factor (PF₁) = 0.65

- Final Power Factor (PF₂) = 0.95

Final Answer:

To raise the power factor from 0.65 → 0.95 at 200 kVA load, the factory needs a ~110 kVAR capacitor bank.

That’s the actual correction size required.

Frequently Asked Questions (FAQ) about Power Factor Correction

What is power factor correction and why is it important?

It’s the process of reducing wasted reactive power. This helps you save on bills, improve efficiency, and prolong equipment life.

How do I know if my power factor is low?

Check your utility bill or run a power analyzer. A factor below 0.9 is often a sign of inefficiency.

Can power factor correction reduce my electricity bill?

Yes. By improving your efficiency, you avoid penalties and cut overall demand.

What devices improve power factor?

Capacitor banks, APFC panels, harmonic filters, and synchronous condensers.

Is power factor correction only for industries?

No. While industries benefit the most, commercial buildings and even homes can gain efficiency through correction.

Conclusion – Why You Should Care About Power Factor Correction

You now understand that power factor correction is not just a technical detail — it’s a practical tool that saves money, boosts efficiency, and contributes to sustainability. By addressing poor power factor, you’re taking control of your energy use and creating a more resilient system.

Don’t wait until you’re paying penalties or replacing burned-out equipment. Start with a power audit today, identify the inefficiencies in your system, and implement the right correction method.

For homeowners or small businesses, you don’t need large industrial banks. You can try a compact option like this Power Factor meter to monitor and improve your system efficiency quickly.